Circular economy: what does it mean?

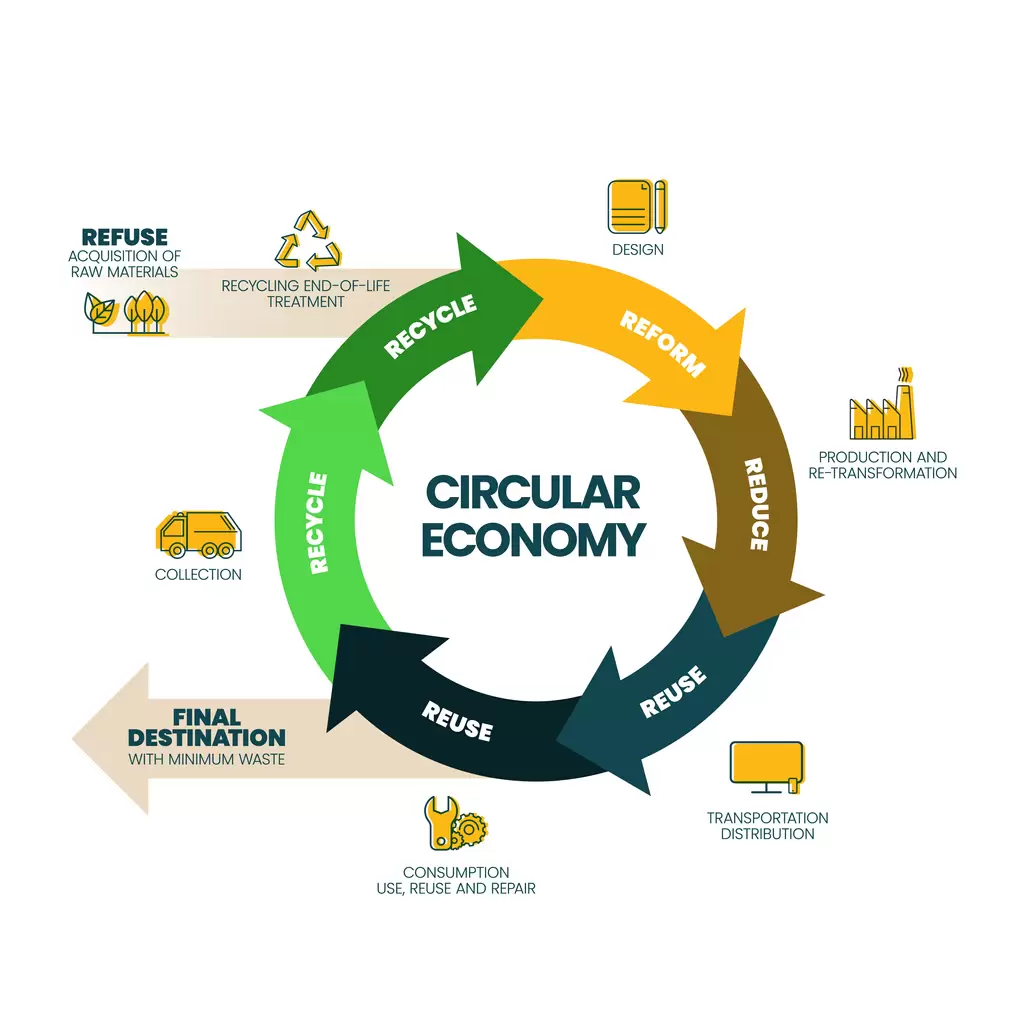

At its core, the circular economy represents a shift from the traditional linear 'take, make, waste' industrial model to an innovative system rooted in the principles of reducing, reusing and recycling. This approach emphasizes the importance of ensuring that resources are used and reused as efficiently as possible within the economy, reducing the need for further extraction and production and thus capturing the economic benefits of improved resource productivity.

Within the circular economy, products, services, waste, materials, water and energy are intended to be used to their maximum value during their lifecycle and then recovered and regenerated at the end of each service life. Encouraging the longevity of product use and the reduction of waste are key aspects of this system. This model allows organizations to become more innovative and competitive, due to greater resource security and the potential reduction of costs.

Companies can employ various strategies to embrace the circular economy. One viable approach is to convert waste into valuable products or services. For instance, by-products from the manufacturing process could be repurposed into new products, creating an additional revenue stream and minimising waste. Other methodologies include product-as-a-service concepts, where organisations maintain ownership of their products and offer them as a service, providing the opportunity for continual maintenance, recovery and upgrade.

Furthermore, embedding eco-design principles into product and service development can also drive circular business and hence a circular economy. Designing items for longevity, reuse and eventual recycling ensures that materials remain in the economic system for as long as possible. Transitioning to renewable energy sources, using circular carbon and promoting systems that increase energy efficiency can also contribute to a more circular economy.

Ultimately, the meaningful implementation of the circular economy requires integrated and coordinated efforts from all stakeholders, including governments, businesses, and consumers. By embracing and advocating for the circular economy, enterprises can build more resilient and sustainable systems, fostering economic growth while improving the health of our planet. The circular economy opens an array of opportunities for businesses to become more innovative, efficient, and competitive, while also promoting sustainability and resilience. It's a win-win approach, offering both economic and environmental benefits.

Benefits of a circular business model

Adopting a circular business model holds remarkable potential, particularly in driving efficiency, fostering innovation and generating economic benefits. The benefits of adopting a circular business model extend beyond the individual company, potentially catalyzing industry-wide change and sustainable development. In fact, focusing on resource efficiency and the reuse of materials and circular carbon can deliver significant economic benefits.

- One of the most apparent benefits of a circular economy model is cost savings. This is achieved through efficient resource use and the extraction of maximum value from materials. Rather than paying for new raw materials, circular economy principles encourage the reuse and recycling of existing resources, which can drastically cut production costs. Furthermore, by extending product lifetimes through repair, remanufacturing and upgrading, businesses can increase their return on investment.

- Enhanced competitiveness provides another critical advantage. In the face of fluctuating commodity prices, building resilience into business models by reducing dependency on scarce resources adds a competitive edge. Circularity can also inspire disruptive innovation, enabling companies to develop new products and services, contributing to job creation and growth in the green economy.

- Moreover, a circular business model can boost companies' reputation. As more consumers demonstrate preference for sustainable and ethically produced products, businesses that visibly commit to circular practices tend to fare better in terms of consumer trust and brand loyalty.

- On a broader scope, circular business initiatives promote environmental sustainability by minimizing waste and reducing the strain on natural resources. This positively impacts biodiversity and combats key environmental threats, notably climate change, by significantly lower carbon emissions compared to linear economic models.

- Further, the circular economy could stimulate economic growth. Studies estimate that a transition toward a circular business model could create millions of jobs globally, while also reducing waste and resource extraction.

In conclusion, the adoption of circular economy principles can be a strategic win for businesses from various sectors, aiding them in addressing cost, consumer expectations, and environmental challenges head-on. As circular economy gains momentum across the globe, the organizations that take the lead in this transition towards circular business will likely see great economic and competitive advantage.

How a circular economy works

Examples of circular economy models

Implementing a circular business model can unlock significant business opportunities and catalyze innovations across various sectors. Here are examples of circular economy models that are making significant strides.

- Product-as-a-Service: This is where businesses sell a service, not a product. This model discourages overconsumption and encourages businesses to make long-lasting products. For example, Phillips' "light as a service" model involves them retaining ownership of their lighting products and taking care of maintenance, repairs, and updates to ensure optimal performance and longevity.

- Remanufacturing: This involves retrieving parts from used products and using them to create new ones. Caterpillar, a construction machinery company, remanufactures parts from old equipment, extending their lifespan, reducing the need for new raw materials, and reducing waste.

- Sharing economy models: Reinforcing the circular economy concept, businesses like Uber and Airbnb encourage sharing resources instead of owning, thus reducing waste and overproduction.

- Resource recovery: Industrial symbiosis is a strategy where waste or by-products of one industry become the raw materials for another. For instance, in Kalundborg, Denmark, excess steam from power plants is used to heat city buildings.

- Circular supplies: This involves supplying products made from circular material streams. In other words, manufactured with fully renewable, recyclable, and biodegradable resources which can be returned to the biosphere. The Dutch carpet manufacturer Desso implements this model by using a specific type of recyclable polypropylene in its carpets.

- Product life extension: Companies may redesign products so they can be easily upgraded or modularly updated. Tech giant Apple encourages this circular business model by offering an iPhone trade-in program where customers can exchange their old phones for a discount on a new one, and the company then recycles the old phone's parts.

- Regenerative resources: Ensuring renewable, reusable, and non-toxic resources secure the economic system's growth and flow. For instance, the paper and packaging company DS Smith has implemented a circular business model based on recycling and producing packaging materials predominantly from recycled fibers.

Finally, the profound adoption and effective implementation of circular economy models require a change in mindset for both businesses and consumers. Circular companies must move from a production perspective to a service-oriented perspective and consumers must transition from ownership to usership.

BioPowder: a circular business model based on circular carbon

Following the above lines of thought, BioPowder is a company born out of circular principles. Our circular business model taps into all of the above concepts due to the fact that it is built around upcycling of by-products in an agricultural environment that strives for carbon neutrality.

- Product origin: BioPowder recovers raw materials from fruit-processing businesses such as olive oil mills, juice and jam factories or almond/pistachio shellers. Through this collaborative approach with other organizations, we ensure continuous supply, even beyond the harvesting seasons. Buying their unused by-products (fruit stones and shells) ensures professional recycling – upcycling in our case – and creates new revenue streams for them. Moreover, fruit stones and shells are a circular material with a carbon content in the range of 50 %. This carbon is the result of carbon capture from the atmosphere by the trees. It can consequently be referred to as circular carbon, i.e. plant-based carbon that is reused at the end of the fruit's lifespan.

- Recovery of by-products: Fruit stones and shells, specifically olive stones, almond shells, pistachio shells, apricot stones and peach stones, are a valuable circular material with enormous potential. As opposed to waste streams, they are raw materials with manifold potential for transformation into natural ingredients and additives. Upcycling is our product strategy: by-products that ended up in landfills in the past are now given a second life with significant added value.

- Resource efficiency and reduced carbon footprint: Our manufacturing activity takes place in close proximity to the raw material sources, hence within an agricultural ecosystem where resources are reused and recycled at a maximum. BioPowder's upcycling technologies involve mechanical processing and do not require any chemicals, additives or major quantities of drinking water. Transforming by-products into micronized powders is a waste-reducing process that opens up many opportunities for circular innovation.

- Collaboration, technology transfer and sharing: Apart from circularity throughout raw material sourcing and powder manufacturing, we engage in downstream circular activity. It means that, apart from supplying our natural particles to end users, we partner with researchers, circular companies, institutes and other stakeholders to drive bio-based innovation. We take a R&D-centered approach and develop know-how to assist clients in the field of material science and green chemistry. Thanks to R&D partnerships, product innovation can be produced and shared efficiently, promoting an accelerated time-to-market, competitive pricing and holistic marketing of new, bio-based products.

Challenges of implementing circular economy models

Implementing circular business practices presents multiple challenges that companies need to address for efficient execution. Key hurdles stem from cultural change, issues of scalability, and initial short-term economic costs.

- Implementing a circular economy necessitates a significant cultural shift within an organization. This means abandoning traditional linear models of production and consumption (make, use, dispose), and instead, adopting an approach where waste is minimized, and materials are consistently re-used and recycled. Effectively making this switch requires a colossal commitment to learning new operational processes, investing in novel technologies, and educating employees about the value of circular practices from both an environmental and economic perspective. This cultural shift is not an overnight exercise and companies must exhibit patience and persistence.

- Operationalizing circular economy principles on a meaningful scale is another significant hurdle to overcome. Many circular practices are relatively easy to establish on a small scale or in a controlled lab setting. However, transitioning these practices to the mass-market level often presents technical challenges and requires substantial investment in infrastructure, resources, and personnel. For example, establishing an efficient take-back system for used products or packaging is far easier in a single store location than it is for a multinational retailer with extensive supply and delivery networks.

- The initial economic implications of transitioning to a circular economy may also act as a deterrent for businesses. The cost of investing in new systems, technologies, training, and infrastructural changes can be substantial. While the long-term benefits – including reduced waste, increased efficiency, and improved corporate reputation – can outweigh these costs, the upfront price tag can still be daunting for many circular companies.

Despite these challenges, there are steps that businesses can take to ease the transition to a circular business model. Creating a detailed plan outlining key steps and a clear implementation timeline can help companies manage the process. Businesses are advised to begin with small, manageable changes that can deliver quick wins before proceeding to more ambitious projects. This approach can also allow organizations to spread the costs involved over a longer period, easing the strain on their finances. Collaborating with other businesses, industry bodies, and government organisations can help share the burden of developing infrastructure and capabilities, making the circular economy transition more achievable for all participants.

Factors needed for successful implementation of circularity

In the transformation towards a circular economy, careful consideration of critical success factors can enable companies to achieve economic value in a sustainable and resource-efficient manner. A few paramount factors, essential for fruitful execution of a circular economy, are outlined below.

- Business model innovation: Adapting products or service designs to facilitate reuse, refurbishment or recycling is integral. This may include practices such as product-as-a-service, where companies retain ownership and responsibility of the product throughout its lifecycle.

- Resource efficiency mindset: Aspiring circular companies need to adopt a paradigm shift in the way resources are viewed. Embracing a use-and-reuse mentality rather than a use-and-discard approach is fundamental.

- Interdisciplinary collaboration: The collaboration of different stakeholders – from policymakers, supply chain partners, to consumers – can foster shared value, aiding in overcoming barriers associated with implementing circular business practices.

- Clear regulation and policy support: Clarity in regulations and firm policy can help guide businesses in the transition towards a circular economy. Existing policies may need to be revised or new policies instated to incentivise companies.

- Investment and Financing: The transition may require substantial investment in new technologies, skills, and research. Robust financial models will be essential in supporting these organisational changes and innovations.

- Education and Awareness: It is vital to build understanding and advocacy of the benefits of a circular economy. This could involve staff training, as well as customer engagement initiatives to drive both supply and demand for circular products and services.

- Technological innovation: Technological tools are critical to track and optimize resource usage, providing transparency throughout the product lifecycle. Innovations such as material-recycling technologies or digital platforms for product tracking can facilitate the adoption of a circular economy.

Effective implementation of a circular business model relies on a combination of these factors, each playing a crucial role in the broader system. While companies may face challenges in the transition, the potential rewards in terms of resource efficiency, cost savings, and improved environmental performance are substantial, and contribute to long-term business resilience.

Role of companies in promoting circular economy

Businesses play a crucial function in realising the potential of the circular economy. Deploying strategic changes in their operational processes, procurement, production, and distribution methodologies, firms can help transition from a linear to a circular model. A linear economy follows a 'take-make-waste' model and leads to several environmental consequences, whereas a circular economy adopts a 'reduce-reuse-recycle' concept that encourages sustainability.

A practical approach could involve firms rethinking their product designs to reduce resource consumption and facilitate easier recycling or remanufacturing. This approach, known as eco-design, can significantly contribute to the circular economy. For instance, designing a product for disassembly enhances the possibility of component recovery at the end of the product's lifecycle, thus promoting reusability and effectively reducing waste.

Incorporating circular supply chain management is another strategy businesses can employ. Firms can opt for responsible sourcing of circular materials, favouring bio-based, renewable or recycled sources, reducing the burden on the planet's finite resources. By ensuring preference is given to suppliers practising sustainable operations, businesses can reinforce the circular economy across the supply chain.

Additionally, companies can foster a circular economy by embracing service-based business models. Shifting focus from selling products to providing services encourages a longer lifecycle for products. Here, maintainability, upgradability and leasing become critical aspects. A service-based model helps conserve resources while simultaneously offering economic benefits like added value, improved customer relationships and a steady stream of revenue.

The promotion of reverse logistics is another way businesses can contribute to the circular economy. By establishing an effective system for the collection and general management of used products, organisations can facilitate waste minimisation and resource optimisation. This strategy can effectively salvage value from old products and reintroduce them into the production cycle.

In essence, businesses must integrate circular economy principles into their core operations and decision-making processes. By doing so, firms can relish the advantages such as cost reductions, resource preservation, enhanced brand image and the ability to tap into new markets. For a more sustainable future, embracing the circular economy is not only a conscientious move; it is a strategic one.

Conclusion

Summarizing the above points, the journey towards a circular business model can be long and daunting. Transformation throughout all processes of an operation certainly takes a shift in strategy, culture and mindset besides significant financial investments – especially at the start.

However, we believe that the benefits of going circular clearly outweigh the costs. Circular transformation is a long-term process which puts aside the focus on short-term gains in favor of lasting environmental and societal health for the long-term. The circular philosophy is about recovery instead of growth, community instead of individualism. In order to be successful and sustainable, circular business models need to produce gains for all stakeholders and the environment.

Please contact us to learn more about circular business and circular carbon upcycling at BioPowder. We look forward to building new partnerships with organizations that share our vision of a circular economy.

FAQ: Circular Economy

What are examples of circular economy and why is it important for businesses?

A circular economy is a system in which resources are used, recycled, and reused to minimize waste and maximize resource efficiency. It is important for businesses because it offers various benefits such as cost savings, enhanced brand reputation, and potential new business opportunities. By implementing circular economy principles, companies can reduce their reliance on virgin materials, lower production costs, and create innovative solutions that align with environmental sustainability.

How can businesses transition to a circular economy?

To transition to a circular economy, businesses can take several steps. Firstly, they can assess their current operations and identify areas where waste can be reduced and resources can be used more efficiently. Secondly, they can adopt strategies such as recycling, reuse, and remanufacturing to extend the lifespan of products and materials. Additionally, businesses can collaborate with other organizations, suppliers, and customers to create closed-loop systems and promote the sharing economy. Finally, investing in research and development for sustainable technologies and materials can also facilitate the transition to a circular economy.

What are the benefits of implementing circular economy principles for businesses?

Implementing circular economy principles can bring several benefits for businesses. Firstly, it can lead to cost savings by reducing the need for virgin raw materials and increasing resource efficiency. Secondly, it can enhance brand reputation and customer loyalty as more consumers are becoming environmentally conscious and prefer companies that prioritize sustainability. Thirdly, circular economy practices can open up new business opportunities, such as offering product repair services or developing innovative recycling technologies. Moreover, businesses can gain a competitive advantage by differentiating themselves as leaders in sustainability and attracting environmentally conscious partners and investors.

Are there any legal obligations for businesses to adopt circular economy practices?

Currently, there are no specific legal obligations for businesses to adopt circular economy practices. However, there are existing regulations and legislation related to waste management, recycling, and environmental protection that businesses need to comply with. Additionally, governmental bodies and international organizations are increasingly promoting circular economy initiatives and providing support for businesses willing to transition to circular practices. While it is not mandatory, adopting circular economy principles can contribute to meeting regulatory requirements, mitigating environmental risks, and positioning businesses as responsible corporate citizens.

How can businesses measure their progress in implementing circular economy practices?

Businesses can measure their progress in implementing circular economy practices by using various indicators and metrics. Some common measurements include resource efficiency ratios, waste generation and recycling rates, carbon footprint, water consumption, and product lifespan. Additionally, businesses can track the adoption of circular economy strategies, such as product longevity, remanufacturing rates, and the percentage of recycled or reused materials in their operations. Regular auditing and reporting can help businesses identify areas for improvement, set targets, and demonstrate their commitment to circularity to stakeholders, customers, and investors.

What are the challenges businesses may face when transitioning to a circular economy?

Transitioning to a circular economy may bring some challenges for businesses. One major challenge is the need for significant changes in business models and supply chain management, which may require investments in research, technology, and infrastructure. Resistance to change within the organization and among stakeholders can also be a hurdle, as shifting to a circular economy often requires a cultural shift and new ways of thinking. Additionally, collaboration and coordination with suppliers, customers, and partners may be required to establish closed-loop systems and shared resource platforms. Lastly, creating consumer awareness and demand for circular products and services can be a challenge, as it may involve educating customers about the benefits and value of circularity.

Is Germany a Circular Economy?

Germany has established itself as a champion of the circular economy, which emphasizes waste reduction, prolonged product life-cycles, and recycling strategies to achieve sustainability. This system creates a closed-loop where resources are utilized to their fullest potential, thereby minimizing environmental impact. A significant directive for companies operating within Germany is the German Closed Substance Cycle and Waste Management Act which promotes the transformation from a traditional linear economy to a circular economy. Enterprises are encouraged to incorporate sustainable practices in their operations, including using renewable resources, optimizing resource efficiency and economic sustainability by practising waste prevention, re-use, and recycling strategies. An example of implemented circular practices is Germany's current waste disposal and recycling system. Enterprises are a part of an extensive system built on meticulous waste separation, leading to a recycling rate of over 60 % – arguably one of the highest rates worldwide. This is a testament to the purposeful roadmap towards a circular economy which affects diverse sectors, not limited to waste management but including design, manufacture, service and product end-of-life strategies. Therefore, Germany can be regarded as an example of a circular economy, setting a pragmatic template for other nations. However, continual evolution and transformation of companies and individuals alike are needed in order to fully embrace and sustain a circular economy.

What are the 4 principles of circular economy?

A circular economy is focused on the sustainability of resources through dynamic business models. This economic approach stands on four vital principles.

- Maintain, Preserve and Enhance Natural Capital: The first principle revolves around the efficient control and moderation of finite resources. By using nature-friendly technologies and renewable energy, businesses can sustain and improve natural capital. It suggests reducing the use of non-renewable resources and preventing ecosystem degradation.

- Optimise Resource Efficiency: The second principle of the circular economy encourages maximising the utilisation of resources by circulating products, components, and materials at their highest utility. This adds value and decreases the total cost of usage or ownership, thus making the system efficient.

- Focus on System’s Effectiveness: The third principle is to create a system that is effective and regenerative by design. It minimises negative external effects, such as emissions and energy leakages, making it safe for the environment.

- Foster Resilience Through Diversity: The fourth principle stresses the importance of diversity within the system. A diverse system can adapt and transform in the face of external shocks with resilience. Therefore, businesses should foster an environment that embraces varied resources, actors, and strategies for a resilient circular economy. Understanding and applying these principles is crucial for companies interested in adopting a circular economy, paving the way for a sustainable, resilient, and prosperous future.